Mines

Mine is one of the hardest places to work. The high temperatures and the large amount of dust represent two of the characteristic elements of this environment and they can compromise the efficiency of the machinery and therefore they make more complicated the workers own work.

The Western Australia Mine is a surface mining and the main focus is to find a lighting tower suitable for this setting.

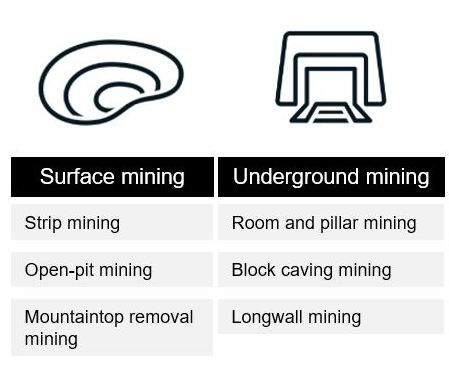

How does a surface mining work?

The surface mining is created with a technique that consist on remove only the earth quantity that is sufficient to pick up the minerals that are shallowly deposited and in the same way in the adjacent areas, without digging vertically deeper.

In fact, as you can guess, the surface extraction is best used for deposit placed horizontally or shallowly.

This kind of surface extraction often involves a big area compared to an underground mine. This happenes because excavation activity continues to move on the surface as superficial deposits are extracted.

Blue Diamond Machinery, distributor of mining lighting towers

Blue Diamond Machinery is the first distributor with head office in Perth, but also has showroom in Sydney, Brisbane and Melbourne. The company, that with its market dominates much of the continent, is an exclusive national distributor for generators, portable air compressor and lighting towers. Blue Diamond Machinery’s strength is its ability to supply high quality equipment, in fact it is one of the most important suppliers for mine site, tier 1 rental and constructions companies.

The reason why the company contacted us is because they needed a lighting tower to use on mine application for a Western Australia customer. So, after a long analysis on our products, we decided to customize one of our lighting towers in order to reflect their needs

Since the mines are natural places where the climate is very hot, it can reach up to 40°C. Among the features that the light tower must have, the ability to withstand high temperatures is another important feature, but not only that. The mines are very dusty places, especially when augers are working. For this reason, the second most important lighting tower characteristic, is to have components that can work despite the dusty environment.

Astrid Mine lighting tower: high temperatures and dusty environment

Do you know that high temperature and dust are the first enemies for mine workers?

They are also enemies for machineries used during the extraction. That’s why the most complete model of the ASTRID range has been chosen for our client Blue Diamond Machinery: ASTRID MINE engine powered lighting tower.

We chose this one because this type of motorized light tower has very high performances, among them, in fact, it has the quality to withstand high temperatures.

In general, on mine site like Western Australia, the climate is very hot, but our lighting towers can work easily. Indeed, high temperatures test the tower, which reacts very well in these environments with temperatures between -30°/+50°.

We have to underline that on mine site the augers are always working day and night. They create a wide horizontal hole to take the mining part and so they produce a large quantity of dust. The dust can act negatively on generator engine, on drills engine and on lighting tower engine too.

Astrid Mine, the lighting tower used in this mine, consists of IP67 approved components.

What does it mean? It means that major lighting tower components have a protection level such that there is no dust deposition inside and protects the effects of temporary immersion in 1 meter of water under condition of time pressure defined by CEI EN 60529.

Illumination system of lighting tower Astrid Mine

On Surface Mining as this one of Australia, there are days when the sun is very schorching, therefore the use of lighting towers is overall at the end of the day, when the sun is less direct, and at night. Astrid Mine tower guarantees until 7800 sq m with 20 lux average and thanks to floodlights’ elettric tilting system you can orient them according to your needs. You can manage it directly from the control panel located on the machine. The light tower running time is 50.000 hours.

When the lighting tower needs maintenance, thanks to the low voltage of illumination system, it guarantees the maximun safety during the use and the repairing. This feature has been appreciated by the customer, because the practicality and the speed of the maintenance in such desert environments is always very important.

The illumination system of the tower is powered by a DeepSea L401 unit control with autostart thanks to dusk and down sensor. The latter then only switches on when there is less sunlight, thus saving on consumption. The unit control has an event scheduler system that allows you to program up to 16 ignitions. The planning allows to preset the lighting events of the lighthouse tower without daily intervention. On mine, in fact, work at a fast pace the event scheduler allows for a bright environment at all times without wasting time on daily interventions to turn the light tower on or off.

How does the lighting tower arrive on mine?

After a long trip overseas in the container ship, the Astrid Mine engine powered light tower unloaded in Australia. The towers arrive at their destination assembled ready for use.

Blue Diamond Machinery takes care of the internal transport. Italtower lighting tower, in particular Astrid Mine, has an approved trailer for circulation on Eu and non-EU roads. It has 2 two wheels all terrain and 1 little wheel, that make the lighting tower more stable during transport.

Another important feature is Amoss Kit, for a safety and intelligent transport. This Kit permits to don’t lift the mast without securing the handbreak, therefore the mast automatically goes down in the case the handbreak is unlocked.

Once they arrive at their destination, the towers are moved by forklifts, thanks to forklift pockets located in the tower base, specially designed for forklift blades can lift a very important weight.

Happy customer

Blue Diamond Machinery is satisfied with our products, it has placed our Astrid Mine lighting tower in one of the biggest Surface mines in Western Australia.

Once in action, our 10 Astrid Mine engine-powered lighting tower illuminate 80000 sq m of the Australian mine so that workers could work in autonomy even at night hours too guaranteeing a operating time of up to 200 hours.

Comments